Explore our full range of industry-leading specialized and custom-made heat treatment equipment, including compact units, data recorders, heating elements, isolation, burners, consumables, spares and accessories.

Cooperheat’s transformer units (Mannings model) have achieved a worldwide reputation for cost effective design, quality and reliability having been successfully operated on heat treatment projects in some of the most demanding climates and industrial environments around the world, for over 50 years

Cooperheat’s Cooper36 has been specifically designed to heat treat up to 36 small tubes and pipes simultaneously. It both reduces costs and time associated with using multiple units to heat treat large volumes of pipe and tubing and provides added safety benefits by working in conjunction with 30V heaters rather than the standard 60V heaters.

The Cooperheat SideKick® is a cutting-edge heat treatment solution designed for maximum efficiency and convenience. Powered directly by a welding power source, this compact unit offers a two-channel resistance heating capability, allowing for precise and controlled heat treatment across multiple zones.

Cooperheat offers the 6-Channel Programmer Model CM-256, designed to improve the reliability, accuracy, and control of six independent heating zones. The programming and operation of the unit are kept uncomplicated and user-friendly through the incorporation of microprocessor-controlled programming, push-button operation, and an LCD display.

Cooperheat's Advantage 3™ 6 Channel programmer/controller has been developed for use in conjunction with any Transformer Power units, which have contactor control sockets, providing automatic temperature process control for up to six Transformer Unit output channels

The Yokogawa uR20000 series temperature recorder is a popular compact paper chart recorder with a recording width of 180mm, the input is universal and highly reliable, with a versatile multi channel digital display, bar graph display, flag display, DI/DO status display and time/date display are provided with 181 x 16 VFD dot display.

The popular 12 point Chino temperature recorder, in stainless steel case, is a basic, analogue alternative to digital recorders. The Chino temperature chart recorder is designed for pre and post weld heat treatment processes utilising type K thermocouples.

Cooperheat designs and manufactures industry-leading Post Weld Heat Treatment Furnaces and Curing Ovens for a range of sectors including oil and gas, power, chemical, heavy fabrication, forging, foundry, and any other industry where heating processes are required. With extensive global experience and expertise, Cooperheat offers unparalleled product excellence.

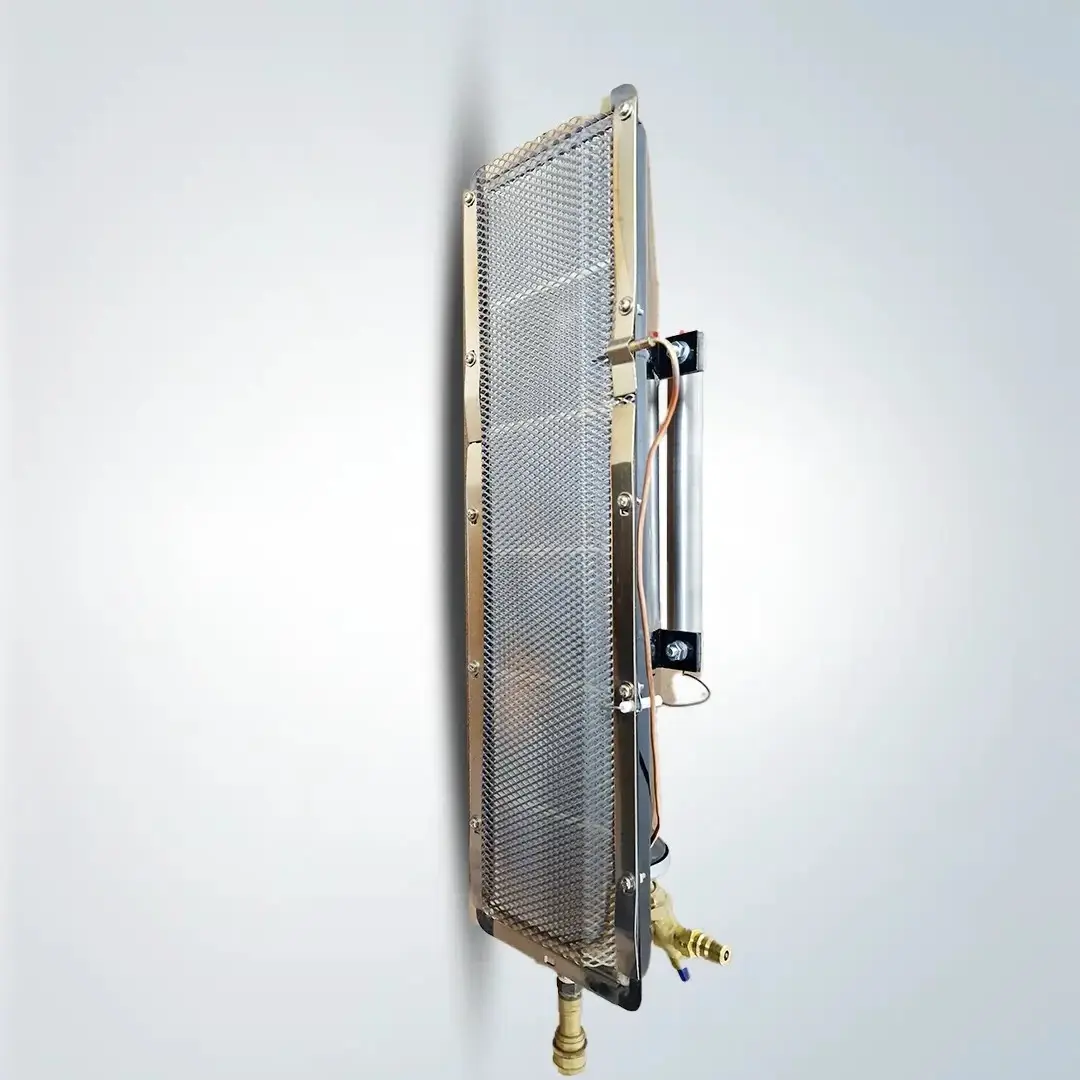

The Cooperheat Surface Combustion Unit (SCU) is an economical and highly efficient infra-red gas radiant heater that provides a radiant heat source for pre-heating metal fabrications and especially useful for preheating rotating fabrications. The SCU is available in a range of sizes.

Let's have a talk! Our experts take the time to discuss your existing challenges and help you make smart decisions about tailor made heat treatment equipment and services that best meet your needs.

GET IN TOUCH